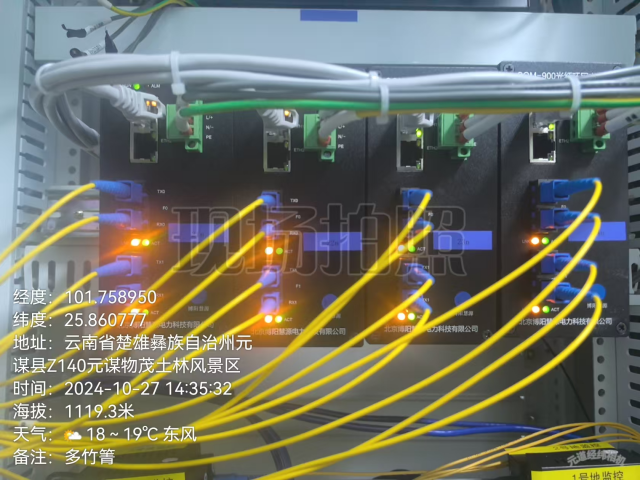

Today we are doing optical fiber equipment maintenance for our customers in Yuanmou County, Chuxiong Yi Autonomous Prefecture, Yunnan Province. Next, I will share with you some of our work processes.

|

|

The first thing we do is a visual inspection to check whether the light is bent, squeezed or broken, and to see if the equipment indicator light is on normally. Then we will do some connection checks to confirm whether the fiber jumper interface is contaminated or loose. Check whether the flange/coupler is aligned and free of dust.

The cleaning tools we usually bring include: dust-free face label, special optical cleaning pen, compressed gas tank, etc. We first disconnect the power supply and clean the interface.

Common problems include:

Weak signal, interruption: We will check for fiber breakage and interface contamination.

High bit error rate: Check for electromagnetic interference and equipment compatibility.

During the inspection process, we must pay attention to safety matters in real time. First, we must confirm that the equipment is powered off to prevent laser direct exposure to the eyes. Then we need to wear an anti-static wristband to prevent static electricity from damaging the equipment.

After completing the maintenance, we will write our maintenance log to record the time of the failure, the phenomenon and the treatment results

|

|