ftth cable factory

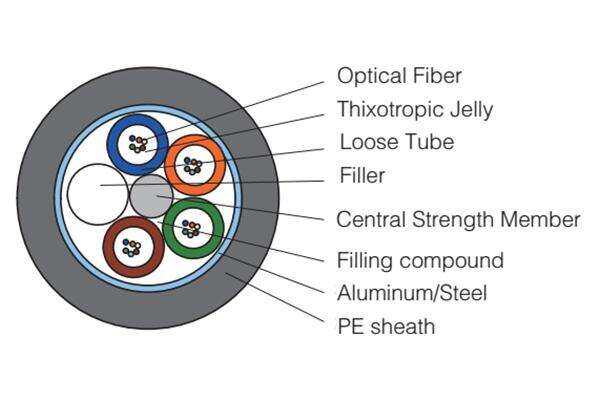

A FTTH cable factory represents a state-of-the-art manufacturing facility dedicated to producing fiber-to-the-home cables that form the backbone of modern telecommunications infrastructure. These specialized facilities integrate advanced production lines equipped with precise optical fiber handling systems, quality control stations, and automated cable assembly processes. The factory encompasses multiple production zones, including fiber drawing towers, buffer tube extrusion areas, strength member application stations, and outer jacket manufacturing sections. Each zone utilizes cutting-edge technology to ensure the production of high-quality fiber optic cables that meet international standards. The facility's main functions include optical fiber processing, cable design and engineering, material testing, and quality assurance. Advanced testing equipment verifies the optical and mechanical properties of cables, ensuring they meet or exceed industry specifications. The factory's technological features include automated production monitoring systems, environmental control systems for maintaining optimal manufacturing conditions, and sophisticated quality control mechanisms that utilize artificial intelligence for defect detection. These facilities typically operate 24/7, implementing lean manufacturing principles to optimize production efficiency and minimize waste. The applications of FTTH cables produced in these factories extend to various sectors, including telecommunications networks, internet service providers, data centers, and smart city infrastructure projects.