producător de splitter plc

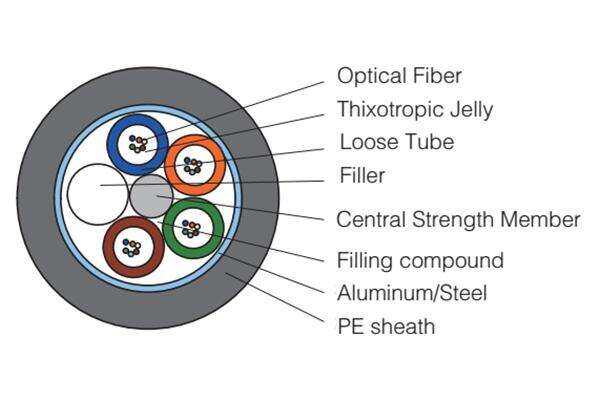

Un producător de splitere PLC se specializează în producerea de componente optice pasive de înaltă calitate, esențiale pentru rețelele moderne de fibra optică. Aceștia folosesc tehnologii avansate de producție și procese ingineriste precise pentru a crea soluții de splitting de încredere care distribuie semnalele optice cu eficiență. Instalațiile lor includ de obicei camere curate moderne, linii de montaj automate și sisteme riguroase de control al calității pentru a asigura o performanță consistentă a produselor. Procesul de fabricație implică tehnici sofisticate precum tehnologia circuitelor luminiscente planare, care permite producerea de splitere cu pierderi de inserare minime și o uniformitate excelentă. Aceștia servesc diferite sectoare, inclusiv telecomunicații, furnizori de servicii internet și centre de date, oferind splitere cu rapoarte diferite de splitting de la 1:2 la 1:128. De asemenea, oferă opțiuni de personalizare pentru a îndeplini cerințele specifice ale rețelelor și condițiilor de mediu. Capacitățile de producție includ adesea atât configurații standard cât și configurări specializate ale spliterei, susținând atât aplicații interioare cât și exterioare. Protocoalele de asigurarea calității implică de regulă mai multe etape de testare, inclusiv teste de stres ambiental, verificarea performanței optice și evaluări ale fiabilității pentru a se asigura că produsele respectă standarde internaționale cum ar fi Telcordia GR-1209 și GR-1221.