drop cable factory

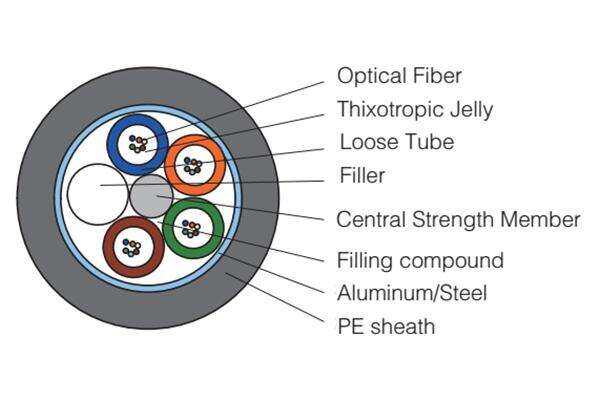

A drop cable factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality telecommunications cables essential for connecting individual subscribers to the main distribution network. These specialized facilities integrate advanced production lines equipped with precision machinery for wire drawing, insulation extrusion, braiding, and jacketing processes. The factory employs sophisticated quality control systems, including automated testing equipment and real-time monitoring devices, to ensure each cable meets stringent industry standards. Modern drop cable factories utilize cutting-edge technologies for material handling, processing, and inventory management, enabling efficient production of various cable specifications ranging from standard RG6 and RG11 to specialized fiber optic drop cables. The facility's production capabilities typically include weather-resistant outdoor cables, indoor installation cables, and hybrid designs that combine multiple transmission mediums. Environmental controls maintain optimal temperature and humidity levels throughout the manufacturing process, while automated packaging systems ensure proper product protection during storage and shipment. These factories also incorporate research and development departments that focus on innovating cable designs to meet evolving telecommunications requirements and improving manufacturing efficiency through process optimization.