ftth-kabelfabrik

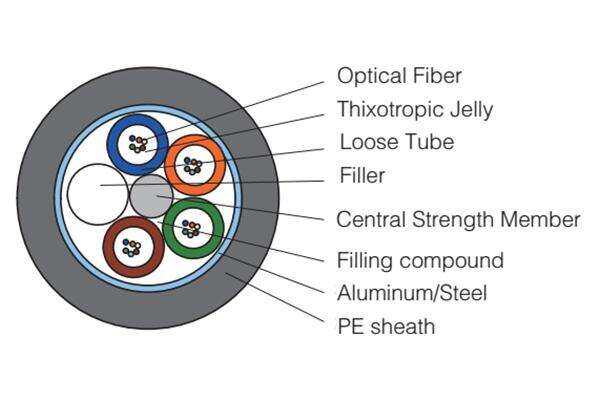

En FTTH-kabelfabrik representerar en modern tillverkningsanläggning som är dedikerad till produktionen av fiber-till-hem-kabler, som utgör ryggraden i den moderna telekommunikationsinfrastrukturen. Dessa specialiserade anläggningar integrerar avancerade produktionslinjer med precis optisk fiberhanteringssystem, kvalitetskontrollstationer och automatiserade kablatsamblingsprocesser. Fabriken omfattar flera produktionszoner, inklusive fiberdragnings torn, bufferrörsextrusionsområden, stationer för styrkeledareapplikationer och yttre skinnstillverkningsavdelningar. Varje zon använder högteknologiska metoder för att säkerställa produktionen av högkvalitativa fiberoptiska kablar som uppfyller internationella standarder. Anläggningens huvudsakliga funktioner inkluderar optisk fiberbearbetning, kabeldesign och -ingenjörskonst, materialtestning och kvalitetsgaranti. Avancerat testutrustningsutrustning verifierar de optiska och mekaniska egenskaperna hos kablar, för att se till att de uppfyller eller överträffar branschspecifikationer. Fabriakens tekniska funktioner inkluderar automatiserade produktionsövervakningssystem, miljökontrollsysteem för att bibehålla optimala tillverkningsvillkor, och sofistikerade kvalitetskontrollmekanismer som använder artificiell intelligens för felupptäckt. Dessa anläggningar opererar vanligtvis 24/7, genom att implementera lean-manufacturing-principer för att optimera produktions-effektivitet och minimera avfall. Tillämpningarna av FTTH-kablar som produceras i dessa fabriker sträcker sig till olika sektorer, inklusive telekommunikationsnätverk, internetleverantörer, datacenter och smart stad infrastrukturprojekt.