प्री कनेक्टराइज़्ड ड्रॉप केबल

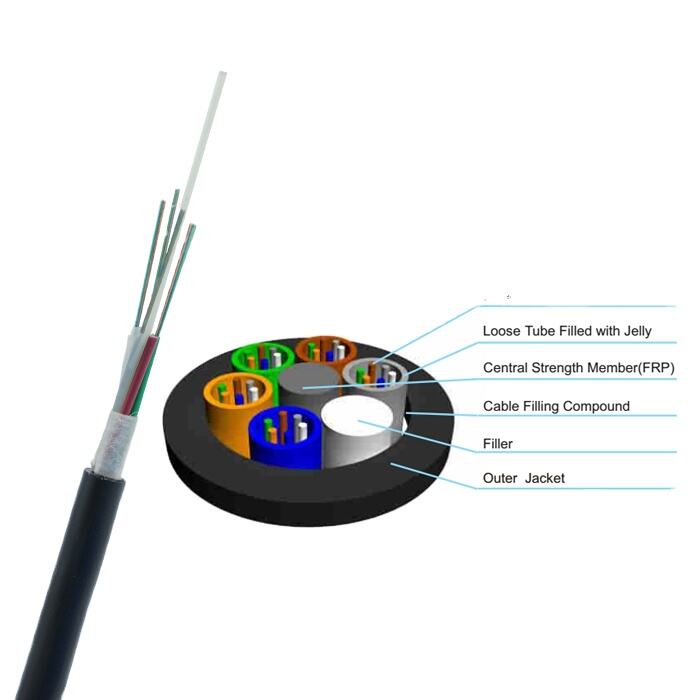

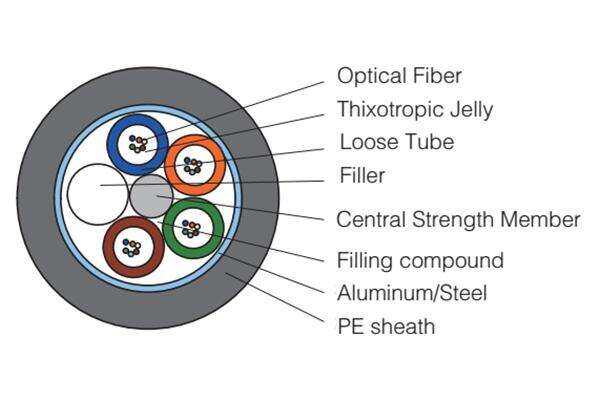

प्री कनेक्टराइज़्ड ड्रॉप केबल फाइबर ऑप्टिक नेटवर्किंग प्रोत्साहन में एक महत्वपूर्ण अग्रगमन है, जो लास्ट-माइल कनेक्टिविटी के लिए एक सरल समाधान पेश करता है। यह रचनात्मक केबल दोनों सिरों पर कनेक्टर के साथ कारखाने में समाप्त होता है, जिससे क्षेत्रीय स्प्लाइसिंग और विशेषज्ञता आधारित स्थापना की आवश्यकता समाप्त हो जाती है। केबल में सामान्यतः एक रोबस्ट बाहरी जैकेट होती है जो फाइबर कोर को बचाती है, जो UV निष्क्रियण, नमी और तापमान चलने जैसी विभिन्न पर्यावरणीय स्थितियों को सहने के लिए डिज़ाइन की गई है। प्री-इंस्टॉल किए गए कनेक्टर, आमतौर पर SC या LC प्रकार के, कारखाने की नियंत्रित स्थितियों में व्यापक रूप से समाप्त होते हैं, जो अधिकतम सिग्नल प्रदर्शन और न्यूनतम इन्सर्शन लॉस को सुनिश्चित करते हैं। ये केबल फाइबर-टू-द-होम (FTTH) अनुप्रयोगों के लिए विशेष रूप से डिज़ाइन किए गए हैं, जो वितरण नेटवर्क और व्यक्तिगत सदस्य प्रीमिसेस के बीच त्वरित और कुशल कनेक्शन सक्षम बनाते हैं। डिज़ाइन में बेंड-इनसेंसिटिव फाइबर तकनीक शामिल है, जिससे फ्लेक्सिबल रूटिंग के दौरान सिग्नल अभिन्नता को कमजोर न करते हुए चला जाता है। इसके अलावा, केबल में टेंशन सदस्यों को समाविष्ट किया गया है जो इंस्टॉलेशन के दौरान और इसके सेवा जीवन के दौरान ऑप्टिकल फाइबर पर तनाव को रोकने के लिए है। निर्माण के दौरान गुणवत्ता नियंत्रण उपाय सुनिश्चित करते हैं कि प्रत्येक कनेक्टर उद्योग की मानक निर्दिष्टियों के अनुसार इन्सर्शन लॉस और रिटर्न लॉस के लिए ठीक से काम करता है, जो विश्वसनीय उच्च-गति डेटा प्रसारण की गारंटी देता है।