Η Σημασία της Κατασκευής του Καλωδίου για τη Σταθερότητα του Δικτύου σε Όλες τις Καιρικές Συνθήκες

Στα σύγχρονα δίκτυα, ένα drop cable παίζει σημαντικό ρόλο στη διασφάλιση ότι η τελική σύνδεση μεταξύ του σημείου διανομής και του χρήστη παραμένει δυνατή και αξιόπιστη. Το τμήμα αυτό του δικτύου είναι συχνά εκτεθειμένο σε εξωτερικές περιβαλλοντικές συνθήκες, καθιστώντας το ευάλωτο σε διάφορες καιρικές συνθήκες. Η κατασκευή, τα υλικά και το σχεδιασμός του καλώδιο πτώσης προσδιορίσετε πόσο καλά μπορεί να αντέξει αυτές τις προκλήσεις. Για πάροχους υπηρεσιών και τελικούς χρήστες, η επιλογή του κατάλληλου καλωδίου είναι περισσότερο από την αρχική απόδοση — αφορά τη διασφάλιση συνεχούς υπηρεσίας καθ' όλη τη διάρκεια του έτους, ανεξάρτητα από τις εποχιακές αλλαγές.

Όταν ένα δίκτυο εξαρτάται από υψηλή απόδοση καλώδιο πτώσης , πρέπει να είναι σε θέση να αντέχει βροχή, χιόνι, ακραία ζέστη και ακόμη και υψηλή υγρασία. Χωρίς την κατάλληλη ποιότητα κατασκευής, αυτοί οι παράγοντες μπορούν να προκαλέσουν υποβάθμιση του σήματος, φυσικές ζημιές ή μειωμένη διάρκεια ζωής του καλωδίου. Γι' αυτό το λόγο, η μηχανική πίσω από την κατασκευή του καλωδίου είναι τόσο σημαντική όσο και η τεχνολογία που μεταφέρει.

Βασικοί Παράγοντες στον Σχεδιασμό Ανθεκτικών στον Καιρό Καλωδίων

Προστατευτική Εξωτερική Θήκη

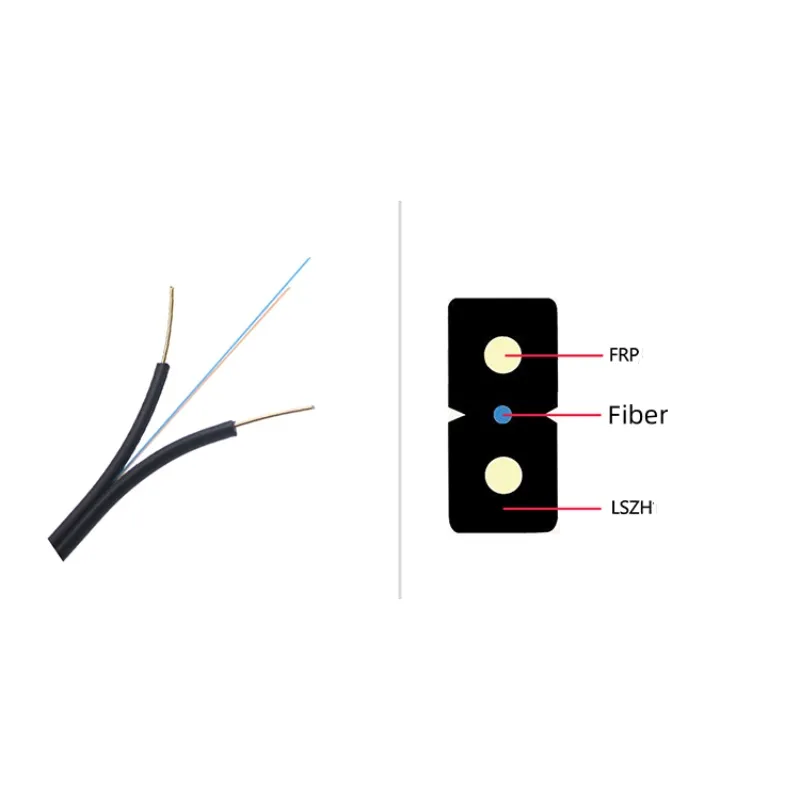

Το πρώτο επίπεδο προστασίας για ένα καλώδιο κατέβασμα είναι το εξωτερικό τσιμούχι του, το οποίο κατασκευάζεται συνήθως από ανθεκτικά υλικά, όπως πολυαιθυλένιο (PE) ή ενώσεις χαμηλής καπνοπαραγωγής και μηδενικής αλογόνης (LSZH). Το στρώμα αυτό προστατεύει τις εσωτερικές ίνες από την υπεριώδη ακτινοβολία, την υγρασία και τη φυσική φθορά. Σε παραθαλάσσιες περιοχές, το τσιμούχι πρέπει να αντέχει στη διάβρωση από το αλάτι, ενώ σε βιομηχανικές περιοχές, πρέπει να αντέχει την έκθεση σε χημικές ουσίες και ρύπους. Ένα δυνατό εξωτερικό τσιμούχι δεν προλογίζει μόνο τη διάρκεια ζωής του καλωδίου, αλλά βοηθά και στη διατήρηση σταθερής ποιότητας μετάδοσης δεδομένων.

Σε περιοχές με έντονη ηλιακή ακτινοβολία, τα περιβλήματα ανθεκτικά στις υπεριώδεις ακτίνες είναι απαραίτητα. Χωρίς αυτήν την προστασία, η παρατεταμένη έκθεση στον ήλιο μπορεί να προκαλέσει τσαλάκωμα του τσιμουχιού, οδηγώντας σε ρωγμές και τελικά σε διείσδυση νερού.

Μέλη Αντοχής και Δομική Υποστήριξη

Στο εσωτερικό ενός καλωδίου πτώσης (drop cable), μέλη αντοχής όπως αραμίδιο νήμα ή χαλύβδινα σύρματα παρέχουν μηχανική σταθερότητα. Αυτά τα στοιχεία προστατεύουν τις ίνες από τη διατάσεις κατά την εγκατάσταση και από την πίεση που προκαλείται από τον αέρα, τον πάγο ή τη βροχή. Ένα καλά σχεδιασμένο σύστημα μελών αντοχής εξασφαλίζει ότι ακόμη και υπό τάση, η ίνα παραμένει ευθυγραμμισμένη, αποτρέποντας την απώλεια σήματος λόγω κάμψης ή μικρορωγμών.

Η ενσωμάτωση αυτών των συστατικών εξασφαλίζει ότι ένα καλώδιο πτώσης μπορεί να τοποθετηθεί αερία, να θαφτεί υπόγεια ή να διατρέξει τα πρόσοψη των κτιρίων χωρίς απώλεια απόδοσης, ανεξάρτητα από τις εποχιακές συνθήκες.

Πώς οι καιρικές συνθήκες μπορούν να επηρεάσουν την απόδοση του καλωδίου πτώσης

Αλλοίωση θερμοκρασίας

Η υπερβολική θερμοκρασία μπορεί να προκαλέσει διαστολή στα υλικά ενός καλωδίου καθόδου, ενώ η υπερβολική ψύξη μπορεί να οδηγήσει σε συστολή. Με την πάροδο του χρόνου, αυτές οι μεταβολές που προκαλούνται από τη θερμοκρασία μπορούν να επηρεάσουν την ευθυγράμμιση των ινών και να αυξήσουν την απόσβεση του σήματος. Τα καλώδια καθόδου που κατασκευάζονται με υλικά σταθερά στη θερμοκρασία, καθώς και με ειδικούς σχεδιασμούς προστατευτικού σωλήνα, βοηθούν στην ελαχιστοποίηση αυτού του φαινομένου και διατηρούν την απόδοση καθ' όλη τη διάρκεια του έτους.

Σε παγωμένα κλίματα, η δημιουργία πάγου μπορεί να προσθέσει βάρος και τάση στα αεριογενή καλώδια. Ένα καλά σχεδιασμένο καλώδιο καθόδου μειώνει αυτόν τον κίνδυνο χάρη σε στοιχεία υψηλής εφελκυστικής αντοχής και χαρακτηριστικά αποκλεισμού νερού που εμποδίζουν την εσωτερική πήξη.

Υγρασία και εισροή νερού

Η βροχή, το χιόνι και η υψηλή υγρασία μπορούν όλα να οδηγήσουν σε εισροή υγρασίας εάν ένα καλώδιο καθόδου δεν διαθέτει κατάλληλη στεγανοποίηση. Το νερό που εισέρχεται στο καλώδιο μπορεί να προκαλέσει παρεμβολές στο σήμα ή φυσική ζημιά στις ίνες. Οι προηγμένοι σχεδιασμοί καλωδίων καθόδου χρησιμοποιούν ζελέ ή ταινίες αποκλεισμού νερού ή ξηρά στοιχεία που διογκώνονται με την επαφή με το νερό για να διατηρούν τον πυρήνα ξηρό ακόμη και σε περίπτωση παρατεταμένης έκθεσης σε υγρές συνθήκες.

Σε περιοχές που πλημμυρίζουν εύκολα, αυτά τα χαρακτηριστικά είναι απαραίτητα για τη διατήρηση της διαθεσιμότητας του δικτύου κατά τη διάρκεια σοβαρών καιρικών φαινομένων.

Δυνατότητες Απόδοσης Ανθεκτικού στις Καιρικές Συνθήκες Καλωδίου Καταβάσεως

Σταθερή Ποιότητα Σήματος

Ένα καλώδιο καταβάσεως υψηλής ποιότητας διατηρεί χαμηλή απορρόφηση και υψηλή χωρητικότητα εύρους ζώνης, ακόμη και σε δύσκολες καιρικές συνθήκες. Με την προστασία της ίνας από περιβαλλοντικούς παράγοντες πίεσης, το καλώδιο εξασφαλίζει ότι η μεταφορά δεδομένων παραμένει σταθερή και γρήγορη. Αυτό είναι ιδιαίτερα σημαντικό για εφαρμογές όπως η ροή πολυμεσικού περιεχομένου υψηλής ευκρίνειας, τα διαδικτυακά παιχνίδια και οι επικοινωνίες επιχειρήσεων σε πραγματικό χρόνο.

Για εγκαταστάσεις fiber-to-the-home (FTTH), αυτή η σταθερότητα εξασφαλίζει στους τελικούς χρήστες ελάχιστη καθυστέρηση και διακοπές, ανεξάρτητα από την εποχή.

Εκτεταμένη διάρκεια ζωής

Η επένδυση σε ανθεκτικό σε καιρικές συνθήκες καλώδιο εγγυάται μειωμένη συχνότητα συντήρησης και αντικατάστασης. Ένα καλώδιο που μπορεί να αντέχει σε διακυμάνσεις θερμοκρασίας, υγρασία και υπεριώδη ακτινοβολία θα διαρκέσει σημαντικά περισσότερο σε σχέση με ένα καλώδιο με ελάχιστη προστασία. Αυτό έχει ως αποτέλεσμα μειωμένο λειτουργικό κόστος για τους παροχείς υπηρεσιών και λιγότερες διακοπές για τους πελάτες.

Η μακροχρόνια αξιοπιστία συμβάλλει επίσης στην αύξηση της ικανοποίησης των πελατών, κάτι που είναι ζωτικής σημασίας στις ανταγωνιστικές αγορές υπηρεσιών δικτύου.

Πρακτικές Εγκατάστασης για Καλώδιο Όλων των Καιρικών Συνθηκών

Κατάλληλη Διαδρομή και Στήριξη

Ακόμη και το καλύτερο καλώδιο μπορεί να υποστεί μείωση της απόδοσης εάν εγκατασταθεί λανθασμένα. Η κατάλληλη διαδρομή αποφεύγει απότομες καμπύλες, ελαχιστοποιεί τη μηχανική τάση και εξασφαλίζει επαρκή απόσταση από πιθανούς κινδύνους. Για αερογειωμένες εγκαταστάσεις, τα επίπεδα τάσης πρέπει να διαχειρίζονται προσεκτικά για να αποφευχθεί η μακροχρόνια πίεση.

Η χρήση σφιγκτήρων, κλιπς και προστατευτικών καλυμμάτων ανθεκτικών σε καιρικές συνθήκες εξασφαλίζει περαιτέρω ότι το καλώδιο θα παραμείνει ασφαλές και λειτουργικό σε περίπτωση ισχυρών ανέμων ή έντονων βροχοπτώσεων.

Προστατευτικά Σημεία Εισόδου

Τα σημεία όπου ένας καταβατικός αγωγός εισέρχεται σε κτίριο ή συνδέεται με εξοπλισμό διανομής είναι ιδιαίτερα ευάλωτα σε ζημιές που σχετίζονται με τις καιρικές συνθήκες. Η κατάλληλη σφράγιση, η χρήση μανικιών και η τοποθέτηση σε προστατευτικούς αγωγούς βοηθούν στην πρόληψη εισόδου υγρασίας και στη διατήρηση της απόδοσης.

Οι τεχνικοί πεδίου πρέπει να διασφαλίζουν ότι αυτά τα σημεία εισόδου είναι στεγανοποιημένα και από το νερό και από τη συμπύκνωση, για να διατηρηθεί η μακροχρόνια αξιοπιστία.

Η Σημασία των Προτύπων Ποιότητας στην Παραγωγή Καταβατικών Αγωγών

Συμμόρφωση με τους Κανονισμούς της Βιομηχανίας

Ένας αξιόπιστος καταβατικός αγωγός πρέπει να πληροί ή να υπερβαίνει τα διεθνή πρότυπα αντοχής σε περιβαλλοντικές συνθήκες, όπως τα πρότυπα IEC και Telcordia. Η συμμόρφωση εξασφαλίζει ότι το καλώδιο μπορεί να αντεπεξέλθει σε διάφορες κλιματικές συνθήκες χωρίς πρόωρη βλάβη.

Τα πρότυπα αυτά παρέχουν επίσης αίσθηση ασφάλειας στους σχεδιαστές δικτύων ότι η επένδυσή τους θα παραμείνει λειτουργική για την προβλεπόμενη διάρκεια ζωής της.

Υλικές καινοτομίες

Οι κατασκευαστές εργάζονται συνεχώς στην ανάπτυξη νέων υλικών για τη βελτίωση της ανθεκτικότητας στις καιρικές συνθήκες. Αυτό περιλαμβάνει καλύτερους πολυμερείς σταθεροποιημένους στο UV, προηγμένες σχεδιάσεις μελών αντοχής και πιο αποτελεσματικές τεχνολογίες αποτροπής της εισόδου νερού. Οι πάροχοι υπηρεσιών που επιλέγουν εύκαμπτα καλώδια κατασκευασμένα με αυτές τις καινοτομίες μπορούν να επωφεληθούν από βελτιωμένη απόδοση και μειωμένα κόστη συντήρησης.

Μελλοντικές τάσεις στην τεχνολογία εύκαμπτων καλωδίων ανθεκτικών στις καιρικές συνθήκες

Έξυπνη Ενσωμάτωση Παρακολούθησης

Ορισμένες νέες σχεδιάσεις εύκαμπτων καλωδίων ενσωματώνουν αισθητήρες που ανιχνεύουν κάμψη, αλλαγές θερμοκρασίας ή είσοδο υγρασίας. Αυτά τα έξυπνα καλώδια επιτρέπουν στους φορείς διαχείρισης δικτύων να παρακολουθούν τις συνθήκες σε πραγματικό χρόνο και να πραγματοποιούν προληπτική συντήρηση πριν συμβούν βλάβες.

Φιλικά προς το περιβάλλον υλικά

Με την αυξανόμενη περιβαλλοντική ευαισθησία, ορισμένοι κατασκευαστές εύκαμπτων καλωδίων εισάγουν εξωτερικές θήκες που μπορούν να ανακυκλωθούν και μη τοξικά υλικά αποτροπής της εισόδου νερού. Αυτές οι καινοτομίες διατηρούν την απόδοση, ενώ μειώνουν την περιβαλλοντική επίπτωση του καλωδίου.

Συχνές Ερωτήσεις

Ποια υλικά κάνουν ένα εύκαμπτο καλώδιο πιο ανθεκτικό στις καιρικές συνθήκες;

Εξαιρετικής ποιότητας εξωτερικές θήκες από πολυαιθυλένιο ή LSZH, σε συνδυασμό με νάιλον ή χάλυβα ενισχυτικά υλικά, βοηθούν στην προστασία του καλωδίου από τις υπεριώδεις ακτίνες, την υγρασία και τις διακυμάνσεις θερμοκρασίας.

Μπορεί ο καιρός να προκαλέσει ζημιές στην απόδοση ενός drop καλωδίου;

Ναι, χωρίς κατάλληλη προστασία, ακραίες θερμοκρασίες, η υγρασία και η έκθεση στον ήλιο μπορούν να προκαλέσουν υποβάθμιση του σήματος και να μειώσουν τη διάρκεια ζωής του καλωδίου.

Πώς η εγκατάσταση μπορεί να βελτιώσει την ανθεκτικότητα στον καιρό στα drop καλώδια;

Η κατάλληλη διαδρομή εγκατάστασης, η διαχείριση της τάσης και η σφράγιση των σημείων εισόδου μειώνουν τον κίνδυνο ζημιών από το περιβάλλον και διασφαλίζουν την απόδοση μακροχρόνια.

Είναι ένα ανθεκτικό στον καιρό drop καλώδιο μια αξιόλογη επένδυση;

Απολύτως, καθώς εξασφαλίζει σταθερή ποιότητα σήματος, μειώνει τα έξοδα συντήρησης και παρατείνει τη διάρκεια ζωής του καλωδίου.

Πίνακας Περιεχομένων

- Η Σημασία της Κατασκευής του Καλωδίου για τη Σταθερότητα του Δικτύου σε Όλες τις Καιρικές Συνθήκες

- Βασικοί Παράγοντες στον Σχεδιασμό Ανθεκτικών στον Καιρό Καλωδίων

- Πώς οι καιρικές συνθήκες μπορούν να επηρεάσουν την απόδοση του καλωδίου πτώσης

- Δυνατότητες Απόδοσης Ανθεκτικού στις Καιρικές Συνθήκες Καλωδίου Καταβάσεως

- Πρακτικές Εγκατάστασης για Καλώδιο Όλων των Καιρικών Συνθηκών

- Η Σημασία των Προτύπων Ποιότητας στην Παραγωγή Καταβατικών Αγωγών

- Μελλοντικές τάσεις στην τεχνολογία εύκαμπτων καλωδίων ανθεκτικών στις καιρικές συνθήκες

- Συχνές Ερωτήσεις